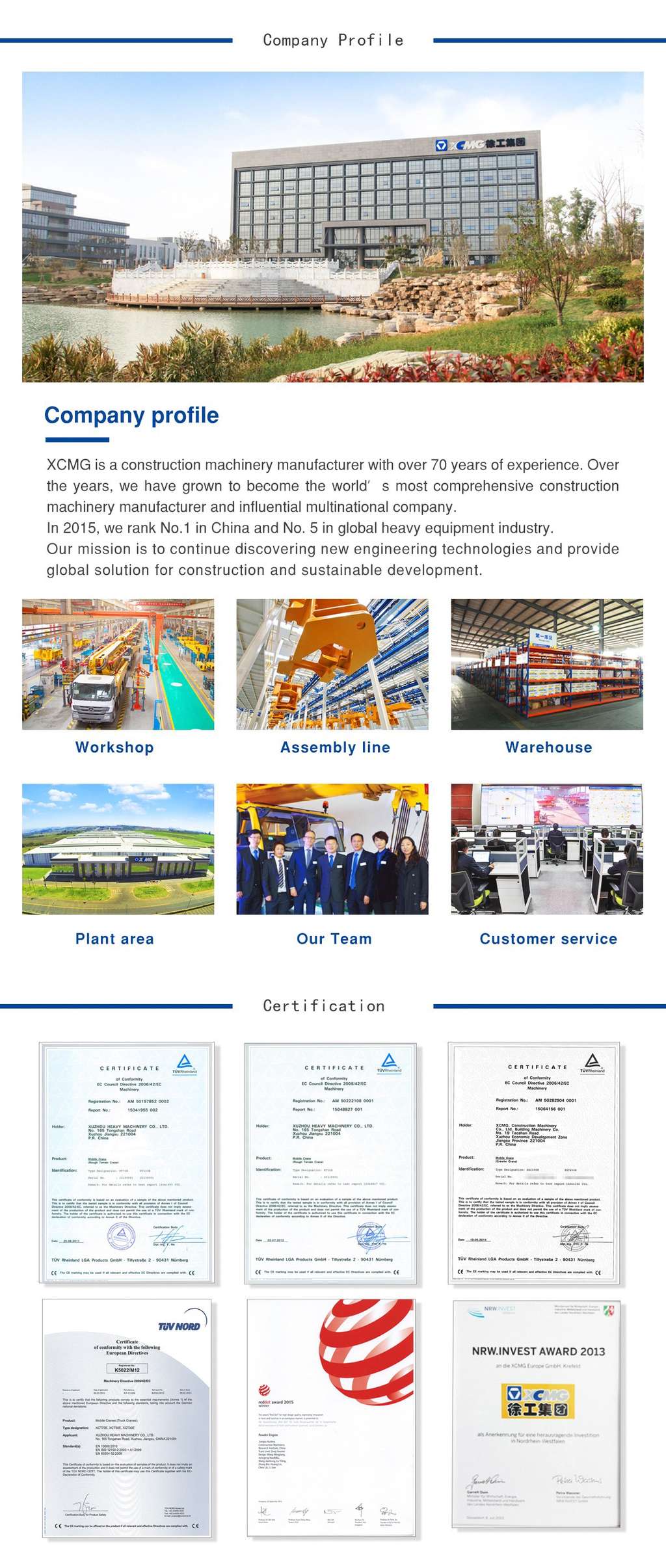

Summary

- Overall Dimension(L*W*H):8612×2490×2980 mm

- Weight:11980 kg

- Model Number: XZJ5161TXS

- Brand Name:XCMG

- Place of Origin:China

- Certification:CE/ISO9001

Specifications

- weight:11980.000kg

- Condition:New

- Moving Type:Wheel

- Chassis Model:DFL1160BX

- Pavement sweep width:3.5 m

- Washing speed:3~10 km/h

- Washing water rated pressure:4 Mpa

- Washing water rated flow:106 L/min

- Sweep width:3.5 m

- Sweeping speed:3~15 km/h

- Maximum cleaning capacity:70000 m²/h

- Maximum inhalation size:—

- Discharge angle:≥45°

- Clear water tank total volume:9 m³

- Trash can effective volume:7 m³

- The lifting Angle:≥45°

- Maximum speed (full load):90 km/h

- Maximum climbing angle:0.3

- Braking distance (full load 30km/h):≤10 m

- Minimum turning diameter:19 m

- Vehicle kerb quality:11980 kg

- Maximum total mass:16000 kg

- Wheelbase:5000 mm

- Front/Rear wheel track:1880/1860 mm

- Approach angle:18°

- Departure angle:11°

- Min. ground clearance:240 mm

- Suction diameter:2×Φ180 mm

- Work ground clearance:5~10mm

- Sweeping diameter:—

XZJ5161TXS Sprinkler-Sweeping Truck

XZJ5161TXS Sprinkler-Sweeping Truck

1、Beautiful and practical Carriage Design

Under the premise of meeting the requirements

of the use and strength, it overall employs SUS304 single-layer stainless steel

production with the advantage of simplicity and practicality and with good

technology. Besides, trash integrates water tank so as to increase the volume

of water, and bring mass production and processing. Trash can be set up within

the anti-overflow alarm device and high pressure spray cleaning device. When it

operates, the anti-overflow alarm device can prevent the sewage from the straw,

which can avoid resulting in secondary pollution. Furthermore, after dumping

garbage, the high pressure spray cleaning device can automatically clean the

tank, greatly reducing the operators’ labor intensity.

2、Cleaning Mechanism with Self-adaptive Control

Ground pressure of side

washing system employs spring as adjustment mode which could adjust the ground

pressure at any time according to the road conditions during work to reduce the

washing wear. In order to reduce the washing wear, ground pressure of side

washing system employs spring as adjustment mode which could adjust the ground

pressure at any time according to the road conditions during work. In order to

solve the problems on sweeper brushes’ obtacles-free, one end of the supporting

oil cylinder employs connected shackle to keep oil cylinder floating. When the

sweeper brushes encounters obstacles, it has the function of automatic

collision avoidance.

3、High

Efficient Duct System

Duct system is the basis of

pneumatic transmission of sweeper-washer vehicle and it includes suction

nozzles, carriage channels and fans. The total three key parts decide the

suction force, air loss, systematic power and etc. And they are the core parts

in the design of sweeper-washer vehicle.

(1)Efficient suctions disc

The vehicle employs a full

floating nozzle structure with double suction nozzle built-in high pressure

spray bar so that the road garbage collection, ground high pressure washing and

sewage recovery function can be achieved completely in one-stop opearation.

(2)Efficient centrifugal fan

It employs high pressure centrifugal fan which is self

developedped and its max air volume can reach 10000m3/h. It has big

full pressure and high efficiency. The fan leaves are made of special steel

materials and their shapes are not easy to wear.

4、Reliable and effective waterway system

(1)Waterway with low pressure and dust

Equipped with stainless

steel sprinkler and with a low-pressure fan-shaped surface of the nozzle, the

scraper can suppress the dust from the brush. Nozzle is also installed with

dust spray pipe and self-made large-diameter nozzle, which can suppress the dust

that comes with picking up the garbage by the scraper.

(2)High pressure waterway

High-pressure pumps are

imported from Itay. When the high-pressure pump starts and the work valves

switch, the pump can automatically unload. With the triple protection of the

air cycle, safety valve and relief valve, high-pressure water pump can be

effectively prevented from damage. The rear part of the car is equipped with

mechanical automatic winding reel and with 20m high pressure hose, which can be

used to clean the body, other equipment and

5、Handy PTO interface

Assistant engine employs

JMCS JX493ZG3 / JE493ZG5. The assistant engine drives hydraulic pump directly

through PTO interface to improve transimission efficiency, reduce trasmission

of supporting housing, save oil consumption, reduce operation cost of users and

decrease the failure rate effectively.

6、Power

Take-off System

Assistant enging of

sweeper-washer vehicle employs automatic clutch output protection device as its

protective setting to ensure the unloading start and stop of assistant engine.

It solve the problem that the power take-off impact is large and it has better

performance in protection of engine, fan and high pressure water pump.

7、Intelligent

Control System

(1)Integrated control mode

The

sweeper-washer vehicle is equipped with advanced intelligent control mode. When

operating, it just needs to select the job mode. Then the operation of

startting and shutting down is automatically controlled by the program. The

operation mode includes full cleaning operation, left washing operation, right

washing operation, full sweeping operation, left sweeping operation, right

sweeping operation and pure suction operation mode etc.

(2)Muti-safety protection

The

muti-safety protection includes voice alarm protection, voice avoidance

warning, voice failure alarming, low water level of clean water carriage, high

water level of garbage carriage, low oil level of hydraulic oil carriage, rear

door unopened alarm, safety supporting which is not put down and other

protective devices. The vehicle has a reverse protection device. That is to

say, the automatic recovery of the work device can be achieved when the vehicle

reverses.

(3)Real-time job monitoring

The

monitoring probe with high-definition is set in the right turret and the rear

of the trash. Besides, a high-definition LCD display ia also set in the cab. As

a consequence, the screen can be switched to the right and the rear of the

trash position respectively so that the quality of vehicle operations can be

monitored.

A high-pressure water pump belt

detection device is set. When the high-pressure pump belt is removed, it

ensures the cleaning can be carried on without water can. When the

high-pressure pump belt can be normally installed, it can alarm, thus

protecting the high-pressure water pump.

8、Safe and reliable hydraulic system

By

adopting the chassis and assistant engine power of the dual-power hydraulic

components system, dumping discharge, nozzle lift and sweep lift can be

achieved by chassis and vice engine. When the dumping is carried out, it is

only necessary to start the chassis engine, without starting the assistant

engine. As a result, the number of revolutions of assistant engine increases.

All these not only extend the service life of the assistant engine but also

save the fuel.

By

using three-valve independent hydraulic system, the hydraulic system work

without interference and is easy to maintain.

By

using plate stack valve procuded by the well-known domestic manufacturers in

Beijing Huade, it is reliable and easy to maintain with stable performance.

9、High Wear Technology

Sweeping and Washing with Mixed Materials

Through

self-development, the proportion of polypropylene, polyethylene raw materials,

inorganic filler and its addictive has been adjusted to design and develop a

formula of brushes which is with excellent performance in friction wear. At the

same time, all experimental formula has been tested to develop speical nylon

sweeping brush hair for Xugong and its service life has been increased two

times.

|

Item |

Contents |

XZJ5161TXS |

||

|

The chassis parameters |

Model |

DFL1160BX |

||

|

Power |

150kw |

|||

|

Wheelbase |

5000mm |

|||

|

Auxiliary engine |

Model |

QSB5.9-C160-30(StateⅢ) |

||

|

Power |

120kw/2200r/min |

|||

|

The vehicle parameters |

Maximum total mass |

16000 |

||

|

Dimensions |

8612×2490×2980mm |

|||

|

Curb mass |

11980kg |

|||

|

Bin parameters |

Bin capacity |

7 m³ |

||

|

The tank volume |

9 m³ |

|||

|

The lifting Angle |

≥45° |

|||

|

High-pressure waterways parameter |

System operating pressure |

5MPa |

||

|

System usage flow |

106L/min |

|||

|

Low-pressure waterways system |

The water pump model |

80QZB60/90 |

||

|

The pump flow |

60m³/h |

|||

|

Rinse the width |

24m |

|||

|

Suction nozzle |

Pipe diameter |

2×Φ180mm |

||

|

Off-ground at work |

5~10mm |

|||

|

Working performance |

Scrubbing operation |

Maximum sweeping width |

3.8m |

|

|

Width of road cleaning and sweeping (excluding the width

of road cleaning) |

3.5m |

|||

|

Cleaning speed |

3~10km/h |

|||

|

Rated pressure of cleaning water |

4MPa |

|||

|

Rated flow of cleaning water |

106L/min |

|||

|

Cleaning operation |

Cleaning the width |

3.5m |

||

|

Sweeping Speed |

3~15km/h |

|||

|

Maximum cleaning capacity |

70000m² /h |

|||

|

Discharging Angle |

≥45° |

|||

|

Low pressure washing width |

24m |

|||

|

Driving performance |

Maximum speed (full load) |

90km/h |

||

|

Maximum climbing Angle |

30% |

|||

|

Braking distance (full load, 30km/h) |

≤10m |

|||

|

Minimum turning diameter |

19m |

|||

|

Structure size |

Wheel track |

Front wheel |

1880mm |

|

|

Rear wheel |

1860mm |

|||

|

Approach Angle |

18° |

|||

|

Departure angle |

11° |

|||

|

Minimum ground clearance |

240mm |

|||

|

Hydraulic system |

The rated pressure |

14MPa |

||

|

Hydraulic oil capacity |

60L |

|||

|

Electrical system |

Chassis system voltage |

24V |

||

|

The working unit system voltage |

24V |

|||