.JPG_l.JPG)

Summary

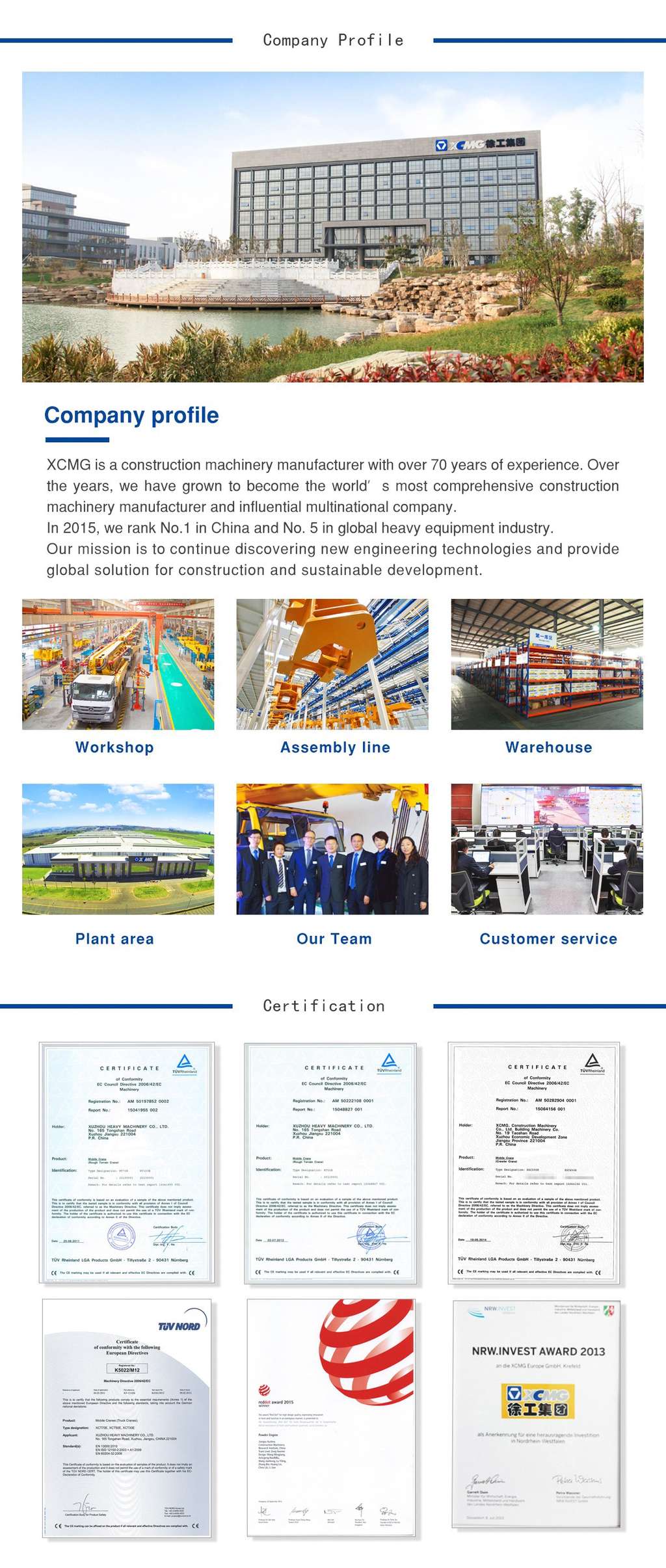

- Brand Name:XCMG

- Place of Origin:China

Specifications

- weight:12200.000kg

- Condition:New

- Moving Type:Wheel

- Color:Red

- Curb mass:12200kg

- Outline dimension (L×W×H):10050×2520×3850mm

- Mixing capacity:8m³

- Cab:G5SD

- Engine model:WP7.300E51

- Drive type:8×4

1.Bright spot of product

NO.1 Ultimately lightweight design

Curb mass of overall unit is not more than 12.2t, meeting the loading requirements of standards and regulations;

The use of lightweight upper structure + fully new lightweight chassis achieves lower oil consumption, more environmental.

NO.2 Drum technology of large capacity and high mixing performance

The protection technology against material overflow with independent patent is adopted to improve drum loading capacity by 6%;

Low tilt angle is designed to achieve an 5% lower tilt angle and 18% higher stability, compared with the counterpart in the industry.

Large rise angle is designed at front cone, with changes on a slump change at all stages of ≤ 5%;

The arc-shaped blade technology with independent patent is adopted to increase charging and discharging speed by 10%.

NO.3 Structure with high reliability

Optimized matching of drum body and blade steel plate realizes equivalent service life of mixing system;

One-piece subframe + triangle stayed beam features super strong bearing capacity, reliability and durability;

Adoption of high-strength wear-resisting liner plate for charging and discharging system prolongs the service life by 50%.

NO.4 Advanced manufacturing technology

Domestically originated cold stamping springback compensation technology is adopted to achieve higher molding precision of the blade;

Special fixture for mixing drum + automatic robot welding technology achieves higher reliability.

NO.5 Application of IT management platform

Three-protection technology (prevent people from stealing oil and concrete, and from loafing on the job) is adopted to make management more convenient;

The dynamic display of concrete weight makes management more intelligent;

Full-view monitoring of dead zone and charging and discharging is provided to achieve accurate and efficient operation.

.JPG_t.JPG)

.JPG_t.JPG)

.JPG_t.JPG)

.JPG_t.JPG)