Summary

- Dimension(L*W*H):6115×2100×2810mm

- Weight:7000kg

- Model Number:HBT6013K

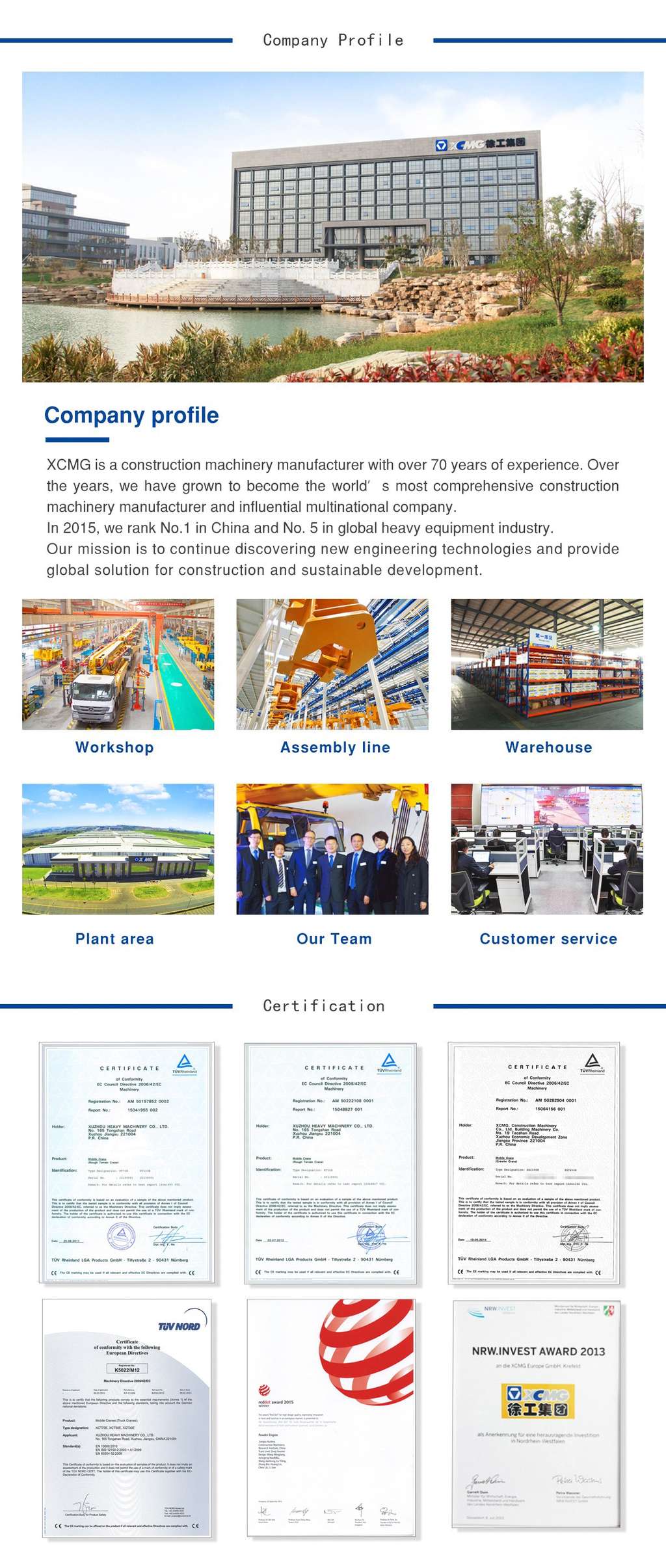

- Brand Name:XCMG

- Place of Origin:China

- Power Type:Diesel

- Type:Trailer-mounted Concrete Pump

- Certification:CE/ISO9001

Specifications

- weight:7000.000kg

- Condition:New

- Moving Type:Wheel

- Concrete delivery value:65/40m³/h

- Max. output pressure:13Mpa

- Hopper capacity/filling height:0.6m³/1370mm

- Concrete slump range:80-230mm

- Concrete delivery cylinder diameter/stroke:200/1400mm

- Rated power:118kw

- Rated rev:2200r/min

- Pressure of hydraulic system:32Mpa

- Rated working flow:260L/min

- Pumping oil cylinder diameter /stroke:125/1400mm

HBT6013K Trailer-mounted Concrete Pump

1、By comprehensively incorporating Schwing switch-over

control technology, the extraction and control of switch-over signal is totally

done by hydraulic pressure, avoiding the unreliability brought by frequent

electrical contact and harsh environment and reducing customers’ later maintenance cost. .

|

Description |

Unit |

Parameter value |

||

|

Construction requirements |

||||

|

Overall performance |

Overall

dimensions |

mm |

6115×2100×2810 |

|

|

Total curb

mass |

kg |

7000 |

||

|

Concrete delivery value |

m3/h |

65/40 |

||

|

Max. output

pressure |

Mpa |

13 |

||

|

Pulling speed |

km/h |

Three-level road 8km/h Road

above two-level16km/h |

||

|

Delivery distance(vertical/horizontal) |

m |

150/600 |

||

|

Hopper capacity/filling height |

m3/mm |

0.6/1370 |

||

|

Concrete slump range |

mm |

80-230 |

||

|

Concrete delivery cylinder diameter/stroke |

mm |

200/1400 |

||

|

Basic configuration |

||||

|

Power system |

Main motor

(diesel engine) |

Model |

WP4G160E331 |

|

|

Rated power |

kw |

118 |

||

|

Rated

rev |

r/min |

2200 |

||

|

Manufacturer |

WEICHAI |

|||

|

Hydraulic

system |

Type |

Open

type |

||

|

Pressure

of hydraulic system |

Mpa |

32 |

||

|

Main oil

pump |

Model and type |

A11VLO130 |

||

|

Rated working flow |

L/min |

260 |

||

|

Manufacturer |

Rexroth |

|||

|

Pumping

oil cylinder diameter /stroke |

mm |

125/1400 |

||

|

Capacity

of hydraulic oil tank |

L |

600 |

||

|

Mixing system |

Large torque at low speed |

|||

|

Lubrication system |

Energy-saving type automatic centralized lubrication |

|||

|

Cooling system |

Air cooling |

|||